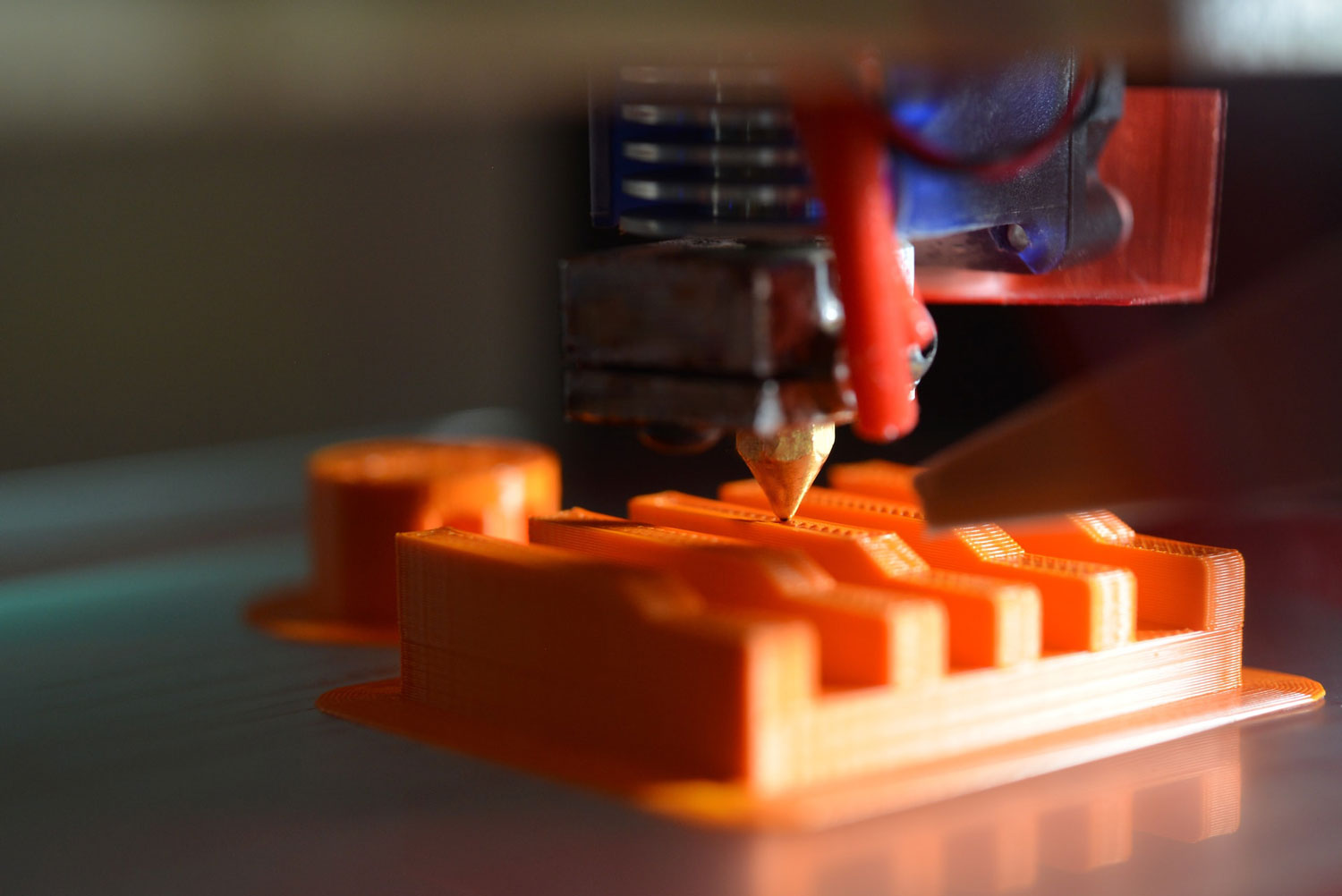

3D printing technology has gained a lot of momentum in the last decade. You might have read articles on how 3D printing has disrupted different markets, including gaming, aerospace, construction, automotive, electronics, and more! There have been speculations that it might replace traditional manufacturing in the coming years. But how far 3D printing technology will go? What are the possibilities of the evolution of this technology in the industry? Will 3D printing completely replace traditional manufacturing or is it a distant dream? Are the concerns cropping up about the viability of traditional printing, right? Let’s find out!

Traditional Manufacturing vs 3D Manufacturing

There is no Yes/No answer to the simple yet complex question, ‘Will 3D printing replace traditional manufacturing?’ However, the ideal answer to his question is, such replacement isn’t feasible in the short term. Such replacement could take years of research, innovation, or improvement. Let’s compare 3D printing and traditional manufacturing based on different attributes and find out where this evolving technology fits in.

Quality Of Production

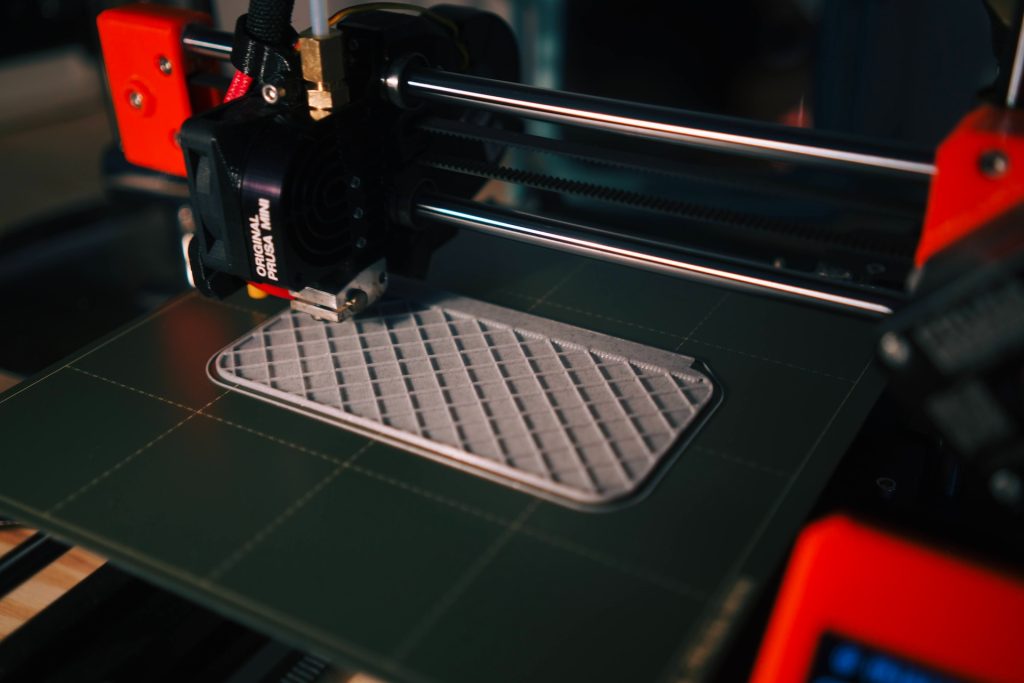

3D printers can produce top-notch quality items. For example, 3D DLP printers can create items with 0.0225mm height on the z-axis that is fine enough to make out even the minute details. Furthermore, sticking to 3D printing is good for creating things like buttons, game pieces, kitchen drawers, toys, or mechanical items.

On the other hand, manufacturing can produce excellent quality products on a large scale too. Unlike 3D printers, manufacturing cover metal casting, lathing, liming, forging, injection plastics, and more! Though you can print an item on a 3D printer, traditional manufacturing can only accomplish the additional finishing steps. As long as 3D printers use layers in the production process, there will be room for traditional manufacturing.

Production Quality

It takes around 3 to 30 hours for a 3D printer to produce an item, based on the complexity. Traditional manufacturing, on the other hand, can produce anything from a few to thousands a day. Also, if you need a product or part that will be globally purchased, you might need more production than what 3D printers can do. Imagine producing a new widget to have in your hardware store; you will need a ton on the same day. Traditional manufacturing with single injection casting could do this.

Production Speed

3D product modeling becomes easier with computer-aided software. Once you have created the 3D model, the 3D printer will take a few minutes to complete the design. In today’s world where companies are agile and creating items quickly is needed, 3D printing shines. With 3D printers, traditional manufacturers could set up production within days that would otherwise take years. Even if you fail with an item, failing fast and moving on to the next product is valuable. It is a wonderful advantage to get to the market quickly, accept feedback, and make necessary changes in the product.

Aesthetics

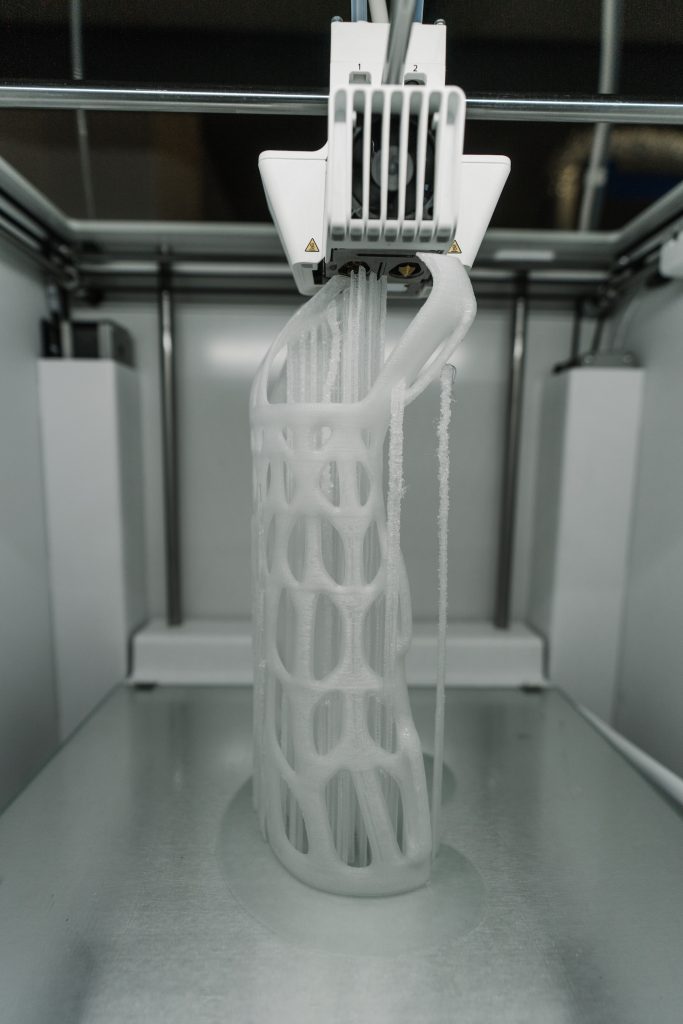

3D printing is generally recommended when a product needs to have a smooth finish. It is an additive process, which means a 3D printer adds layers of materials onto a product until it is complete. You can easily see cross-sectional thin layers. On the flip side, the manufacturing process includes steps, like stamping, molding, etc., that create a smoother finish.

Strength

3D printed products are not as strong as traditionally manufactured ones. When it comes to injection molding, the part of a product has is evenly strong because the material structure is consistent. However, a 3D printed product consists of layers. This means, layers don’t bond well in Z-axis as they do in X-axis and Y-axis; thus, they are weak. Another reason why 3D printed products are weak is, they can use only a few plastics for production. Or, one can’t use a range of high-performance plastics.

So, will 3D Printing Replace Traditional Manufacturing?

Well, considering the comparison we have done above, it would take decades for 3D printing to replace traditional manufacturing. In the near future; however, we can say that 3D printing could modify or improve some processes in the industry.

Thus, rather than considering 3D printing as a replacement for traditional manufacturing, consider it as a way to expand the manufacturing field or improve the manufacturing processes.